CHDL series vertical ring pulse-type high gradient magnetic separator is the strongest magnetic equipment with the best performance, state-of-the-art technology at home and abroad. This equipment fundamentally solved the blocking problem of horizontal ring magnetic separator & high gradient magnetic medium, with advantages of high concentration ratio, strong adaptability to feeding ore granularity, density and grade fluctuation, reliable operation, easy maintenance, etc. Achieving concentrate ore with high grade and high recovery rate by picking weak magnetic ore.

Working Principle

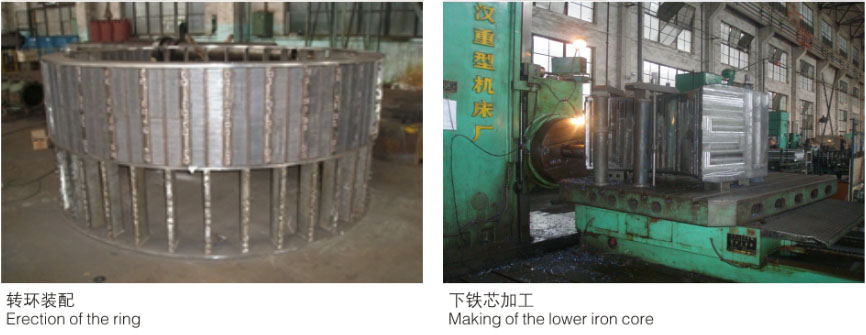

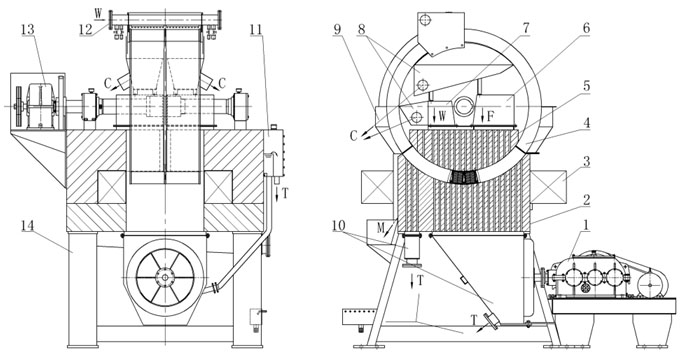

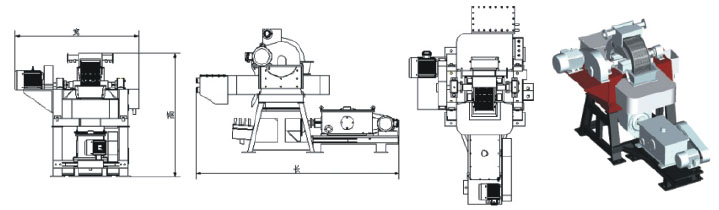

Magnetic separator consists of idler wheel, medium box, assembly part of up & low iron cores, excitation coils, ore feeding hopper, concentrate hopper, middle hopper, tailing hopper, concentrate flushing device and pulsation generator.

1.High frequency vibrating mechanism 2.Bottom iron yoke 3.Excitation coils 4.Rortary ring 5.Upper iron yoke 6.Feeding ore hopper 7.Water rinsing hopper 8.Concentrate hopper 9.Middle hopper 10.Tailings hopper 11.Liquid level box 12.Concentrate flushing device 13.Rotary ring driving mechanism 14. Rack

F-Ore feeding W–Water C–Concentrate M-Middlings T–Tailings

Magnet conductivity stainless steel bar medium box or stainless steel mesh magnet medium pile is installed with Rotary ring(4). During mineral selection, rotary ring(4)rotates clockwise, and ore slurry will be fed from feeding hopper(6),then flowing through the circle in rotary ring along gap of upper iron yoke(5),the magnetic medium is magnetized in magnetic field, forming high gradient magnetic field in surface, magnetic particles in ore slurry are attracted to the surface of magnetic medium, rotary ring(4)takes it to the top of nonmagnetic field area, and then washed into concentrate hopper by flushing water of concentrate flusher(12),nonmagnetic particles via inner annulus to outer annulus flow into tailings hopper(10) along gap of bottom iron yoke(2)and then discharged.

Main Features

* High gradient magnetic separator adopts vertical ring rotation, reverse flushing the ore. CHDL series separators adopt the vertical ring rotation type, for each group of magnetic medium, the direction of reverse flushing is opposite to the feeding direction, and the coarse particles can be flushed out by water without passing through the magnetic medium pile. Thereby it effectively avoids magnetic mediums blocking.

* Using ore slurry pulsing mechanism to drive ore slurry to generate pulsating hydro-force. Under the action of pulsating hydro-force, the mineral granules in the slurry are always scattered, which improves the quality of magnetic concentrate.

* Horizontal ring magnetic separator has strict requirements to the feeding particle granularity. We designed the unique magnetic system structure &optimized combination of magnetic medium which raises the upper limit of mineral grain size up to 2.0mm, simplifies the mineral grading work and increased adaptability of separator.

* High magnetic field strength, the background magnetic field is up to 1.3T, the surface magnetic field of medium box is up to 2.6T.

* Due to the special design of the medium box, magnetic field can generate high gradient magnetic field within high density and disorderly bars medium structure.

According to attractive force formula of magnetic field to material F=K×X×B×ΔH×V, which illustrates high gradient magnetic field makes it easier to attract paramagnetic mine.

F:attractive force; K: coefficient; X: specific susceptibility; B: flux density; ΔH: gradient; V: materials’ volume.

* Outlet box is simple, beautiful and easy connection to the site interface.

* With automatic precaution function. When the cooling water pressure is insufficient or the cooling water outlet temperature is too high, the system will give sound and light to alarm, meanwhile it will automatic cut off power supply, thus service life is extended.

* Technical parameters, like magnetic field, ring rotating speed, pulse box stroke & pulse box frequency all are adjustable, thus it is easy for user to finalize the optimum technical parameters.

* The electrical control cabinet adopts air cooling, which is more reliable and safer.

Application Range

Separation of weak magnetic minerals, such as: hematite, limonite, siderite, chromite, titanic iron ore, scheelite, wolframite, manganese and tantalum-niobium ores, etc.

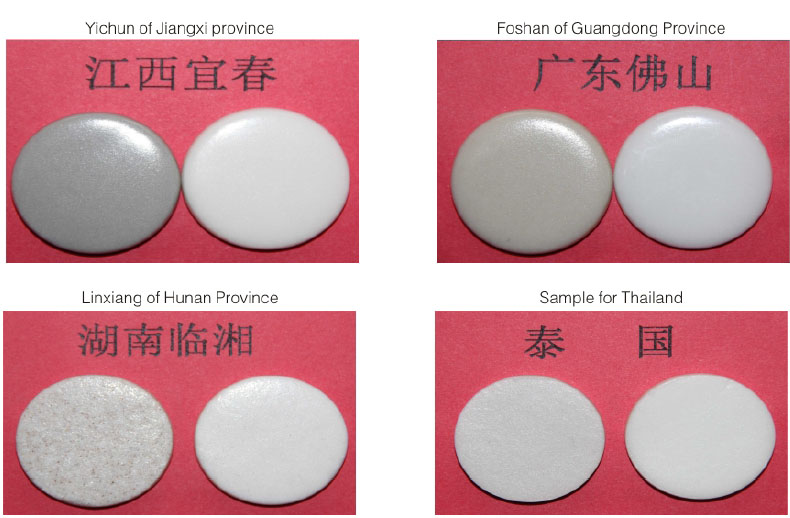

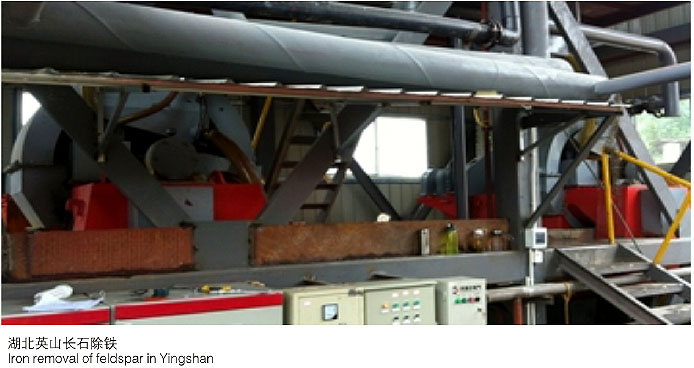

For iron separation from nonmetallic minerals, such as quartz, feldspar, nepheline, fluorite, sillimanite, spodumene and kaolin, etc.

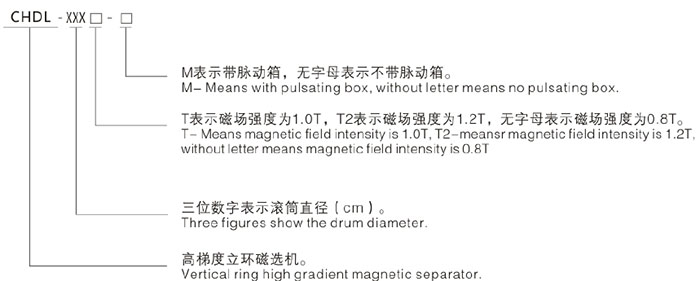

Model Designation

(Medium Magnetic Separator)Main Technical Parameters

| Model | CHDL-50-M | CHDL -75-M | CHDL -100-M | CHDL -125-M | CHDL -150-M | CHDL -175-M | CHDL -200-M | CHDL -250-M | CHDL -300-M |

| Outer Dia. Of ring(mm) | 500 | 750 | 1000 | 1250 | 1500 | 1750 | 2000 | 2500 | 3000 |

| Rotate speed of ring (r/min) | 0.3~3 | 0.3~3 | 0.5~4 | 0.5~4 | 0.5~4 | 1~4 | 1~4 | 1~4 | 1~4 |

| Feeding size(mm)(-200 mesh %) | 1 | 1 | 1.2(30~100) | 1.2(30~100) | 1.2(30~100) | 1.2(30~100) | 1.2(30~100) | 1.2(30~100) | 1.2(30~100) |

| Feeding density(%) | 10~40 | 10~40 | 10~40 | 10~40 | 10~40 | 10~40 | 10~40 | 10~40 | 10~40 |

| Throughout capacity of ore slurry(m³/h) | 0.25~0.5 | 0.5~1.0 | 12.5~20 | 20~50 | 50~100 | 75~150 | 100~200 | 200~400 | 350~650 |

| Handling capacity of dry ore(t/h) | 0.03~0.125 | 0.06~0.25 | 4~7 | 10~18 | 20~30 | 30~50 | 50~80 | 100~150 | 150~250 |

| Rated background field strength(T) | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 |

| Rated excitation current(A) | 1200 | 1100 | 650 | 850 | 950 | 1200 | 1200 | 1400 | 1400 |

| Rated excitation voltage(V) | 8.3 | 12 | 26.5 | 23 | 28 | 31 | 35 | 45 | 62 |

| Rated excitation power(kW) | 10 | 13 | 17 | 19 | 27 | 37 | 40 | 63 | 87 |

| Power of ring motor(kW) | 0.37 | 0.55 | 1.1 | 1.5 | 3 | 4 | 5.5 | 11 | 18.5 |

| Power of pulse motor(kW) | 0.37 | 0.75 | 2.2 | 2.2 | 4 | 4 | 7.5 | 11 | 18.5 |

| Pulsionstroke(mm) | 0~40 | 0~40 | 0~30 | 0~20 | 0~30 | 0~30 | 0~30 | 0~30 | 0~30 |

| Times of pulse (times per min.) | 0~400 | 0~400 | 0~300 | 0~300 | 0~300 | 0~300 | 0~300 | 0~300 | 0~300 |

| Water supply pressure(MPa) | 0.1~0.2 | 0.1~0.2 | 0.2~0.3 | 0.15~0.3 | 0.2~0.3 | 0.2~0.3 | 0.2~0.3 | 0.2~0.4 | 0.2~0.4 |

| Water consumption(m³/h) | 0.75~1.5 | 1.5~2.5 | 10~20 | 30~45 | 60~90 | 80~120 | 100~150 | 200~300 | 350~530 |

| Cooling water flow(m³/h) | 1.5~2 | 1.5~2 | 2~2.5 | 2.5~3 | 3~4 | 4~5 | 5~6 | 6~7 | 8~10 |

| Main body weight(ton ) | 1.7 | 3 | 6 | 14 | 20 | 35 | 50 | 105 | 175 |

| Max. unit weight(t) | 0.3 | 0.6 | 2.22 | 4 | 5 | 11 | 14 | 15 | 16 |

| Overall Sizes (L×M×W) mm | 1800×1400 ×1320 |

2000×1360 ×1680 |

2700×2000 ×2400 |

3200×2340 ×2700 |

3600×2900 ×3200 |

3900×3300 ×3800 |

4200×3550 ×4200 |

5800×5000 ×5400 |

6600×5300 ×6400 |

Note:

1. Model selection principle: according to the handling capacity of ore slurry.

2. Model selection principle for dry nonmetallic minerals: handling capacity of dry ore should be half one of the above table.

(Strong Magnetic Separator)Main Technical Parameters

| Model | CHDL-50T (T3) | CHDL -75T(T3) | CHDL -100T(T3) | CHDL -125T(T3) | CHDL -150T(T3) | CHDL -175T (T3) | CHDL -200T(T3) | CHDL -250T(T3) | CHDL -300T (T3) |

| Outer Dia. Of ring(mm) | 500 | 750 | 1000 | 1250 | 1500 | 1750 | 2000 | 2500 | 3000 |

| Rotate speed of ring (r/min) | 0.3~3 | 0.3~3 | 0.5~4 | 0.5~4 | 0.5~4 | 1~4 | 1~4 | 1~4 | 1~4 |

| Feeding size(mm)(-200 mesh %) | 1 | 1 | 1.2(30~100) | 1.2(30~100) | 1.2(30~100) | 1.2(30~100) | 1.2(30~100) | 1.2(30~100) | 1.2(30~100) |

| Feeding density (%) | 10~40 | 10~40 | 10~40 | 10~40 | 10~40 | 10~40 | 10~40 | 10~40 | 10~40 |

| Throughout capacity of ore slurry(m³/h) | 0.25~0.5 | 0.5~1.0 | 12.5~20 | 20~50 | 50~100 | 75~150 | 100~200 | 200~400 | 350~650 |

| Handling capacity of dry ore(t/h) | 0.03~0.125 | 0.06~0.25 | 4~7 | 10~18 | 20~30 | 30~50 | 50~80 | 100~150 | 150~250 |

| Rated background field strength(T) | 1(1.3) | 1(1.3) | 1(1.3) | 1(1.3) | 1(1.3) | 1(1.3) | 1(1.3) | 1(1.3) | 1(1.3) |

| Rated excitation current(A) | 1200 | 1200 | 1200 | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 |

| Rated excitation voltage(V) | 13.4(20.3) | 20.3(25) | 26.5(37.8) | 28.5(40) | 34.7(44.3) | 38.2(51.5) | 39.2(56.2) | 56(78) | 80(93) |

| Rated excitation power(kW) | 16(24.4) | 24.4(30) | 31.8(45.4) | 40(56) | 46.8(62) | 53.5(72) | 55(78.7) | 78.4(109.2) | 112(130.2) |

| Power of ring motor(kW) | 1.1 | 1.1 | 1.5 | 3 | 4 | 7.5 | 11 | 15 | 18.5 |

| Power of pulse motor(kW) | 0.37 | 0.75 | 2.2 | 2.2 | 4 | 4 | 7.5 | 11 | 18.5 |

| Pulse stroke(mm) | 0~40 | 0~40 | 0~30 | 0~20 | 0~30 | 0~30 | 0~30 | 0~30 | 0~30 |

| Time of Pulse (times per min.) | 0~400 | 0~400 | 0~300 | 0~300 | 0~300 | 0~300 | 0~300 | 0~300 | 0~300 |

| Water supply pressure(MPa) | 0.1~0.2 | 0.1~0.2 | 0.2~0.3 | 0.15~0.3 | 0.2~0.3 | 0.2~0.3 | 0.2~0.3 | 0.2~0.4 | 0.2~0.4 |

| Water consumption(m³/h) | 0.75~1.5 | 1.5~2.5 | 10~20 | 30~45 | 60~90 | 80~120 | 100~150 | 200~300 | 350~530 |

| Cooling water flow(m³/h) | 1.5~2 | 1.5~2 | 2~2.5 | 2.5~3 | 3~4 | 4~5 | 5~6 | 6~7 | 8~10 |

| Main body weight(t) | 2.1 | 3.6 | 6.8 | 16 | 25.5(26.8) | 41.3(42.6) | 55(57) | 113(118) | 188(196) |

| Max.unit weight(t) | 0.5 | 0.9 | 2.5 | 6 | 5.8(7.6) | 9(11.5) | 20(21.5) | 19.5(22) | 21(22) |

| Overall dim.(L×M×W) | 1400×2000 ×1600 |

1500×2000 ×2100 |

2100×2600 ×2800 |

2600×2950 ×3150 |

2950×3550 ×3600 |

3600×3370 ×4100 |

4200×3700 ×4630 |

5650×5150 ×5900 |

6450×5500 ×6550 |

Note:

1. Model selection principle: according to the handling capacity of ore slurry.

2. Model selection principle for dry nonmetallic minerals: handling capacity of dry ore should be half one of the above table.

3. According to the separation effect, we don’t recommend pulsating box to nonmetallic minerals selection, if needed, parts of pulsating box can be supplied.

4. In the technical parameters table, the separator weight, max.unit weight and overall diameter are parameters for separator with no pulsation box.

Optional Equipment for Separator

KYTS Series Drum Screen

Application Range

Since the magnetic separator is a kind of separator which has requirements for materials’ particle sizes, ore slurry should be first separated by drum screen before entering the separator. Drum screen not only can be used as slag removal equipment for CHDL vertical ring magnetic separator, but also be used in metallurgy, mining, chemical abrasive and other industries which need slag removal equipment.

Technical Features:

①It rotates steady with low speed, featured high liability, low maintenance rate and long service life. It is not easy to block, especially it is suitable for separating damp materials

②The area of screen is big enough, it can touch materials alternately thus the service life has been prolonged.

③The screen features low noise, totally sealed structures and no dust contamination.

④The screen can be separated with different sizes thus it can be adapted to variable particle sizes products.

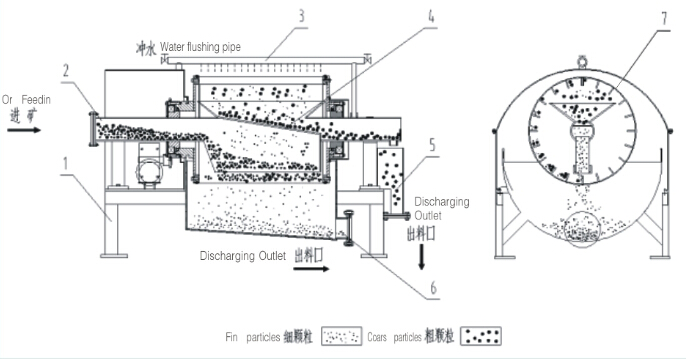

Structure & Working Principle

1.Rack 2.Material feeding pipe 3.Water flushing pipe 4.SS screen 5.Coarse particles discharging outlet 6.Fine particles discharging outlet 7.SS screen

1.Rack 2.Material feeding pipe 3.Water flushing pipe 4.SS screen 5.Coarse particles discharging outlet 6.Fine particles discharging outlet 7.SS screen

The drum screen will rotate under the force of driving mechanism, ore slurry from the lower left part can be poured to the drum screen circle, fine particle ores and water will fall to the ore bucket through screen, and then they will flow to the CHDL magnetic separator by fine particle pipes for separation. The coarse particles will be transmitted to top by slag carrying plate and coarse particles will be flushed into the recycling hopper at last.

Specification

Specification & Technical parameters for drum screen

|

Model Parameter |

KYTS—8010 | KYTS—1210 | KYTS—1415 | KYTS—2019 | KYTS—2529 |

| Drum Dia.(mm) | Φ800×1000 | Φ1200×1000 | Φ1420×1500 | Φ2000×1950 | Φ2500×2950 |

| Particle granularity(mm) | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

| Pulp density(%) | ≤50 | ≤50 | ≤50 | ≤50 | ≤50 |

| Max.processing capacity(t/h) | 15 | 45 | 75 | 150 | 300 |

| Max.feeding volume(m3/h) | 50 | 100 | 200 | 400 | 800 |

| Transmission power(kW) | 1.5 | 1.5 | 2.2 | 4.0 | 7.5 |

| Water consumption(m3/h) | 1~2 | 3~5 | 5~10 | 10~20 | 20~30 |

| Weight(t) | 1.35 | 2.2 | 4.2 | 6.9 | 10.5 |

| Overall dimension(L×W×H) | 2400×1300×1500 | 3000×1450×1700 | 3500×1600×2250 | 4200×2200×2700 | 5500×2750×3050 |

| According to mine density, granularity &process position to select the right CHDL separator | CHDL—75CHDL—100CHDL—125 | CHDL—125CHDL—150 | CHDL—150CHDL—175CHDL—200 | CHDL—200CHDL—250 | CHDL—200CHDL—250CHDL—300 |

Screen size can be customized by requirements of users.

Lab

By stimulating the real beneficiation process, we design an automatic beneficiation line which consists of crushing equipment, ball grinding machine, grading, mangetic separation, flotation. Complete experiments can be done in this Lab for customers. Also by the test Lab, the test result can be analyzed instantly & accurately. In order to enhance the credibility of the data, and offer the reasonable data for actual equipment model selection & technical process, the actual production process is maximally simulated during the test process in the lab.

Magnetic separation Lab for metallic mineral

Full view

Full view

High gradient vertical ring magnetic separator with 2 levels

Ball Grinding Machine

Full view

Wet drum type adjustable magnetic separator